McLaren MP4/4 New Electronics

18th July 2016 12:25

OLDtronics were commissioned to reverse engineer the electronics on a McLaren MP4/4 (Honda V6 turbo) while the original electronics were working, then to supply a pin-compatible modern ECU.

The project involved:

- Reverse engineering the entire chassis and engine harness to establish the ECU pin-out.

- Establishing the engine sequence with reference to the crank mounted sensor and the two cam mounted sensors that each supplied two signals, one as a cam synchronisation and the second as a backup cranks sensor.

- Determine the sensor calibration for all the sensors.

- Construct a test harness and connect the ECU to a Hardware-in-the-Loop tester (HiL). The HiL can stimulate the crank/cam and other sensor inputs while measuring the ECU outputs such as ignition and injection phase and timing.

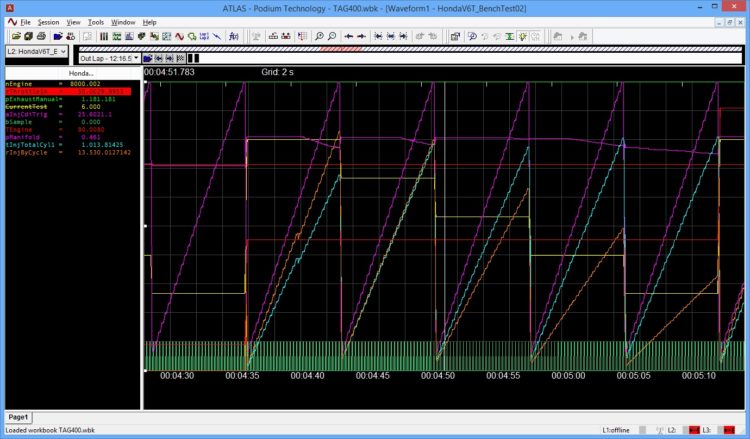

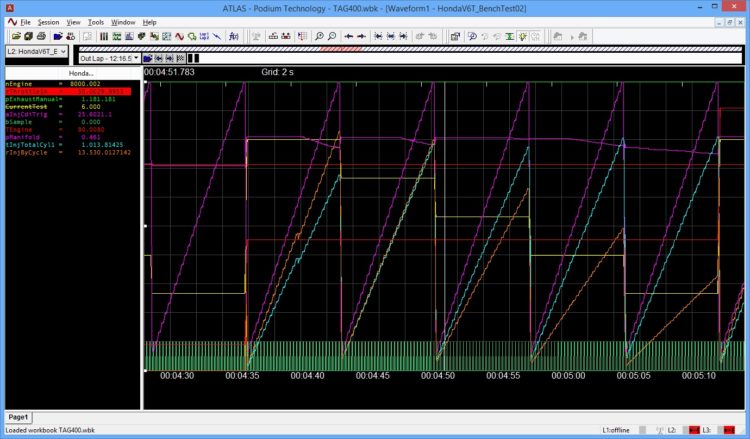

- Develop test scripts to exercise the ECU over its entire operating range to establish its internal workings:

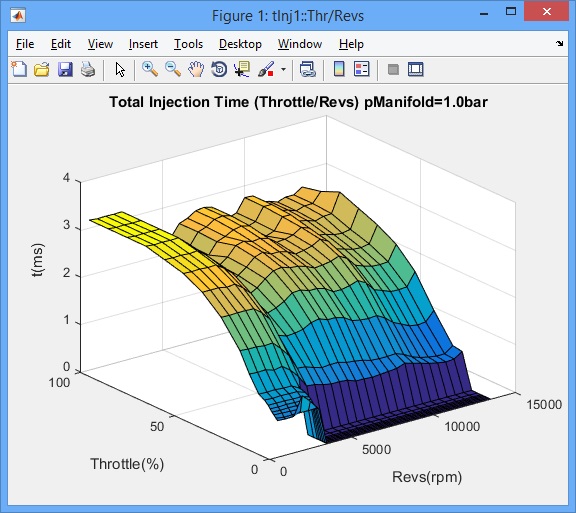

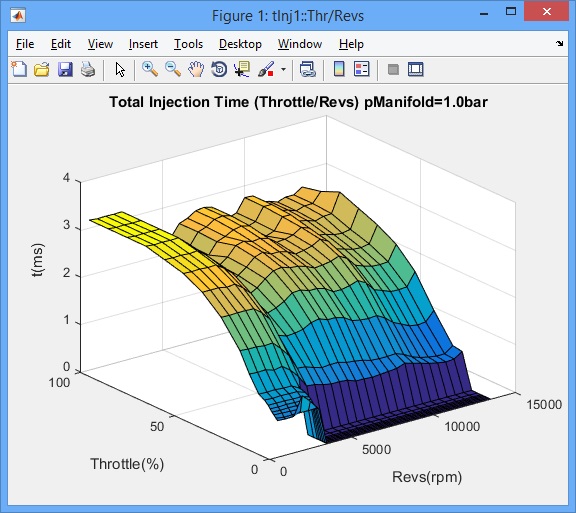

- Injection on time maps for revs, throttle and boost pressure

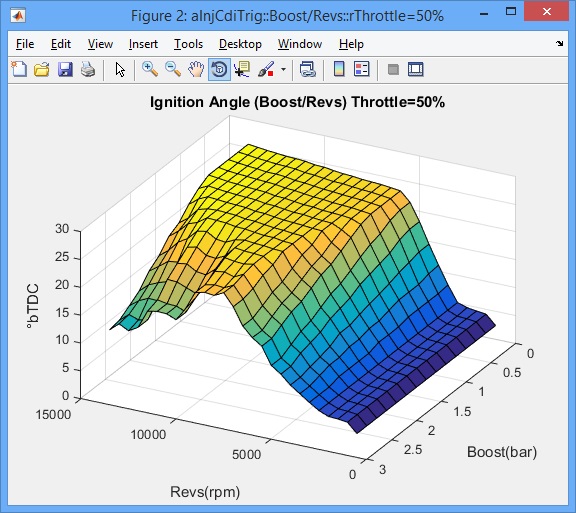

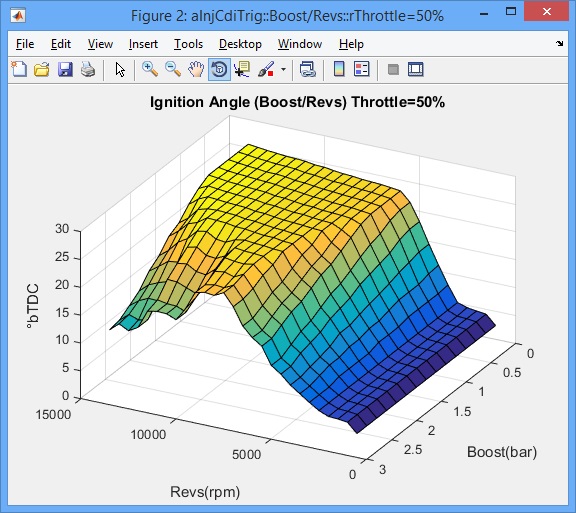

- Ignition firing angle for revs, throttle and boost

- Injection start/end angles

- Ignition dwell time

- Engine temperature compensation for injection and ignition

- Air temperature compensation for injection and ignition

- Fuel temperature compensation for injection and ignition

- Fuel pressure compensation for injection

- Understand the wastegate control strategy

- Understand the fuel temperature control strategy – the engine largely runs on toluene which is best heated to around 50°C to get the best atomisation.

- Understand the intercooler bypass strategy

- In order to be able to keep the original dash, the serial data stream from ECU to the dash had to be decoded, which turned out to be one of the hardest tasks. This ended up having to produce a PC program that has developed into the Honda ECU Monitor

- The original CDI unit was used initially, requiring the input pulse stream to be decoded.

- Develop Simulink models using @Source from Podium Technology to recreate the functionality of the original ECU. Simulink and @Source were chosen and the most future proof method of documenting the work. Even if the replacement ECU becomes obsolete the models can be quickly applied to an even newer ECU.

- Develop a CAN-bus to dash serial bus interface using Arduino hardware as the ECU did not support the peculiar 9-bit serial stream.

- Produce a McLaren TAG400 in a box machined to be identical to the original ECU and to also be pin-compatible.

- Compare the results of running the original ECU over its entire range with the results from the replacement ECU. The target being to run the car without having to remap the ECU.

- Add a modern GPS logger and camera to the car, for which an AiM Solo was selected, interfacing to the CAN data stream from the modern ECU. An Arduino interface was also produced that converted the dash serial stream to CAN so the original ECU could be connected to the logger.

- Run the car at a track. After some tweaks to the wastegate tuning, the car ran perfectly.

Using the HiL system to stimulate the original ECU connected to engine harness

Original dash display

Original ECU connected to the HiL

Reverse engineered ignition timing map

Reverse engineered injection on-time map

Data log of ECU going through its sweeps

Decoding crank and cam timing

Car ready for first shakedown at Silverstone

Car ready for first shakedown at Silverstone

Addition of AiM logger and camera

On track with Chris Goodwin driving